Three Things You Can Do To Reduce Drag In Co2 Cars

CO2 car racing encompasses many aspects of engineering, not the least of which is aerodynamics 1. Since most CO2 cars in a given class weigh about the same and have the same amount of thrust, making the body as sleek as possible can give you a real edge over the competition on race day. Some of these aero tricks can be applied to an existing car while others may require an entirely new chassis.

Snow And Ice Accumulation And Shedding

Very little information could be found regarding test or modeling results of how ice and snow can accumulate on aerodynamic devices.

Boat tails can significantly affect the flow field directly behind a van semi-trailer and it is also expected that snow could accumulate on top of the bottom boat tail panel. However, very little relevant work could be located to quantify how this change in flow field would affect vehicles following behind a trailer equipped with a boat tail or the way in which snow and ice accumulates and sheds from truck aerodynamic devices. . NRC-CSTT recommends performing a similar study to the NRC-IAR study in which many aerodynamic devices were sequentially added to a tractor and trailer combination. However, for this study, the emphasis would be on ice and snow accumulation and shedding, rather than aerodynamic drag. Ideally, a scale model vehicle would be placed in a high speed wind tunnel at sub zero temperatures and snow and ice would be blown against the model vehicle. The amount of snow accumulation and shedding could be measured against a baseline vehicle that was placed beside the test vehicle. Downstream effects on a scale model passenger car following the trailer could also be monitored to determine if the snow and ice would be more likely to accumulate on a trailing vehicle and also to determine if the forward vision of drivers in trailing vehicles is affected in any way.

Improving Aerodynamics To Boost Fuel Economy

Automakers have been interested in aerodynamics at least since the introduction of the Chrysler Airflow in 1934. But the need to improve fuel economy in recent years has pushed aerodynamics toward the top of automakers’ priority lists.

It turns out we the car-buying public have helped cause this emphasis on aerodynamics. You see, the easiest way to improve a vehicle’s fuel economy is to make it smaller and lighter and give it a smaller engine. But we want 400-hp sports cars and seven-passenger SUVs and 5,000-pound-capacity tow vehicles and we want good gas mileage, too.

Lucky for us automakers have found a way to do that: by making their vehicles slip more smoothly through the air.

“The main driver for lower aerodynamic drag is fuel economy,” says Max Schenkel, General Motors technical fellow, aerodynamics. “As long as federal standards for fuel economy increase and fuel costs go up, aerodynamic drag will have to be improved.”

In fact, today’s wisdom says you can’t start measuring a vehicle’s aerodynamics too early in the design process. From the earliest conceptual stages on through the working-prototype stage, automakers rely on computer software and wind tunnels to ensure vehicles meet their aerodynamic targets.

Volvo’s Frasher says the force acting against a car by the air it moves is a function of:

To improve Cd, designers may make the following changes:

How to Improve the Aerodynamics of Your Car

You’ll also improve aerodynamics by:

Also Check: How To Get Car Title Florida

The Effect Of The Canadian Climate On Drag

Air density is another factor that can affect drag, as was shown in Equation 1. As temperature drops, the density of the air increases which increases the drag on a vehicle. This can cause significant changes in drag on a vehicle in climates such as Canada where temperature differences of 60 degrees Celsius can occur in the same location when comparing July conditions to, say, February conditions. Table 3 illustrates the approximate increase in drag at various temperatures when compared to the reference temperature of +15 °C.

|

18.5 |

In cold Canadian climates, the aerodynamic drag in winter can be nearly 20% greater than at standard conditions, due to the ambient air density. For highway tractor-trailers and intercity buses, this results in about a 10% increase in fuel consumption from drag when compared to the reference temperature, further emphasizing the importance of aerodynamic drag reduction strategies for the Canadian climate.

How Is Friction Created In An Engine

For the typical vehicle with an internal combustion engine, only about 15% to 20% of the energy from its fuel is used to power it down the road. The majority of the energy is lost to powertrain inefficiency caused by friction and heat. The modern internal combustion engine has dozens of moving parts. Those parts can rub against each other, creating tremendous friction that not only saps the engine of its efficiency, but can damage it as well.

Friction is caused when molecules come into close contact with each other and their properties create drag. When you are holding your childs hand crossing the street or applying the brakes in your car, you count on friction to work for you. The more friction, the better. But friction also has its drawbacks and sometimes you wish it didnt work so well. This is especially true inside machinery.

Read Also: How To Get Out Of A Car Contract

Adjusting Vehicle Shape To Reduce Drag

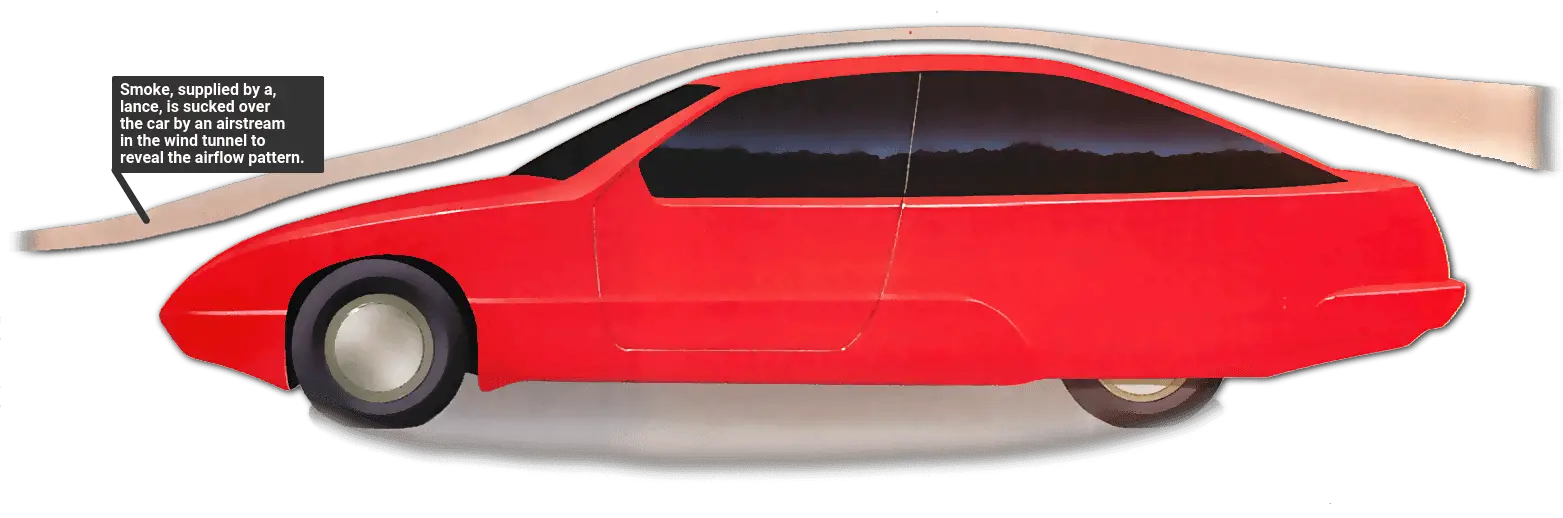

Although this design was emulated in various streamlined concept car models, the shape was found to be impractical when designing an actual car, mainly due to the long and narrow end. Instead, designers created cars with a profile more comparable to that in Fig. 4.

However, the air that flows around the car swirls around the rear much more for the actual vehicle profile as compared with the teardrop profile. These swirls are called vortices, and they represent a low-pressure area behind the car. The low pressure behind the car creates a suction effect that tries to pull the vehicle backwards . Therefore, reducing the size of the separation zone, which is the area behind the car containing the vortices behind the car, is one of the predominant methods of decreasing aerodynamic drag. This can be done by slightly tapering the rear end of a car to reduce the size of the separation zone. As counterintuitive as it may seem, the rear section of the car is the cause of the most drag on a vehicle . This is the same reason why the example of holding a traffic cone outside of a car window has less drag when pointed away from the direction a vehicle is moving. An example of streamlining a car by tapering the rear end of the vehicle can be noted by examining the design of the Maybach Exelero .

Additional Methods Of Drag Reduction

In addition to streamlining the rear section of the car and the bottom of the car, another method of reducing drag is due to a phenomenon called skin friction. Since air is a viscous fluid, meaning that the air molecules can exert forces on one another, a thin layer of air will attach itself to the body of a vehicle in motion and exert a frictional force upon the vehicle. This section of slow-moving air located very close to the body of the car is called the boundary layer, and it increases the skin friction of the car, thus increasing the total drag a vehicle must overcome . In order to reduce drag from skin friction, the surface of the car should be highly polished and clean, thereby reducing the amount of friction that the boundary layer can exert on the car . In addition to having a highly polished surface, other small protrusions, such as screws, hinges, and gaps in the body work should also be minimized to reduce drag created from skin friction.

Recommended Reading: Register A Car In California From Out Of State

How Do You Reduce Drag On A Co2 Dragster

dragsterfrictionreducecarDrag

Also Know, what is the most aerodynamic shape for a co2 car?

- Wedge – A good aerodynamic shape because of it’s long gradual slope. Which allows the air to travel over the surface easily.

- Lift – an upward force resulting from air being forced underneath a car.

- When a car is too heavy, it is hard to get into motion but once in motion it stays in motion easily.

Beside above, how do you reduce drag on a car?

Adjust the front fascia and air dam to reduce drag under the vehicle.You can reduce your vehicle’s aerodynamics by:

How do you make a co2 dragster?

How Does Friction Damage An Engine

Friction not only creates resistance it also generates heat. Heat, especially in metals, creates expansion, which compromises tolerances and precise measurements in pieces of machinery that are not intended to warp or expand out of line. In engines, friction also causes wear of metals and plastics at a microscopic level. Little bits of debris shear off the gears and cams of the parts inside your engine. Eventually, with shafts and bearings moving at many thousands of times per minute, this friction will begin to wear down the internal parts of your engine, transmission and differential. Combine that with heat, and you are looking at a rapidly deteriorating situation.

Friction damages not only a powertrains moving parts, but the engines efficiency as well. And reduced efficiency means reduced mileage, reduced horsepower and torque, reduced engine life, increased maintenance costs, and increased emissions.

Recommended Reading: How To Check Water In Car

Reducing The Drag Resistance Of Automotive Cars By Diminishing The Wake Separation Zone

2039

REFERENCESSection:

How Fuel Is Consumed In A Heavy Truck

Fuel is consumed by a vehicles engine as it travels on the road, with engine power output contributing to five primary factors, as listed in Table 1. Depending on the duty cycle of the vehicle , the contributions to fuel burn of these five factors change in proportion to one another as identified in Table 1. For example, in an urban environment the power dissipated through acceleration and braking of the vehicle is the dominant loss, whereas on the highway the aerodynamic losses are dominant. Lightweight hybrid vehicles with energy-recovery braking systems are potentially a good solution for reducing fuel consumption under urban environments, as proposed for urban-specific vehicles such as transit buses . For the highway environment, in which most commercial goods are shipped, aerodynamic losses which are dissipative and cannot be recovered are the dominant source for power and fuel consumption. Motor coaches, which predominantly travel between major city centres, show a similar power loss-breakdown to the highway conditions on Table 1, but with a greater proportion dissipated through aerodynamic losses due to the lower rolling resistance associated with lower vehicle weight. The reduction of aerodynamic losses is a significant area in which fuel consumption improvements can be made.

Table 1 – Engine Power Balance for Fully-Loaded Class 8 Tractor Trailer

|

10-25% |

35-55% |

Recommended Reading: How Much Mileage On A Car Is Too Much

Recent Programs Findings And Recommendations

There is a wide range of technology currently available or under development that could provide significant drag reduction of tractor trailers. In recent years, several programs in Canada, the Unites States, and Europe, have been looking at evaluating drag-reduction devices for the transportation industry. Those programs that have provided the most input in preparing this document are:

A recent report by the US National Academy of Sciences has documented current and emerging technologies for reducing fuel consumption of medium- and heavy-duty vehicles . This report has provided, in part, a basis for new US EPA and NHTSA rules governing the fuel consumption and emissions of such vehicles, under the US Clean Air Act and the Energy Independence and Security Act of 2007 . The final rules governing this program became effective in November 2011 and provide the regulatory framework in which medium- and heavy-duty engine and vehicle manufacturers must comply with the Clean Air Act beginning with the 2014 model year, with full compliance by model year 2016. In regards to the effect of aerodynamics on fuel consumption, manufacturers will be required to report the aerodynamic drag of their vehicles based on a standard method.

The NAS report provided four main findings with regards to aerodynamic technologies for the reduction of fuel consumption of medium- and heavy-duty vehicles, summarized in the following:

Aerodynamic Devices For Buses

The applicability of aerodynamic add-on devices for use on long haul intercity motor coach buses has been less well studied than those of class 8 tractor trailers. The North-American bus fleet is much smaller than the tractor-fleet and consequently, the annual fuel consumption and GHG emissions by intercity buses are significantly lower.

A typical highway coach exhibits a number of aerodynamic advantages over a class 8 tractor-trailer: there is no tractor-trailer gap the body comes lower to the ground effectively incorporating side skirts and a flat front end eliminates the multiple aerodynamic discontinuities typically caused by radiator-hood, hood-windscreen and windscreen-fairing locations. Consequently, a stock long haul highway coach may have a CD as low as 0.384.

The dominant contribution to the aerodynamic drag of an intercity bus is the pressure differential between the forward- and rearward-facing surfaces of the body, with a minimal contribution from skin friction.

About 60 to 70 percent of the total wind-averaged drag of a bus is attributed to pressure loads acting on the vehicle forebody, making it the principal area for drag reduction strategies. By far the most efficient method of reducing forebody drag is to minimize flow separation by combining the rounding of the forward corners with the tapering of the forebody.

Read Also: Program Honda Key To Start Car

Model Scale Evaluation Of Drag Reduction Technologies

The largest detriment to wind-tunnel testing of full-scale heavy vehicles is the size of the vehicles and the time required to prepare them for testing. The two sets of full-scale tests described above , , required the tractors and trailer to be lifted by crane into the wind tunnels. Safely rigging and lifting such vehicles is difficult and labour-intensive, resulting in expensive setup costs. Model changes are also time-consuming when dealing with full-scale parts. Model-scale testing eliminates some of these challenges. Combined with the ability to test scale models at or near design Reynolds numbers with ground effect simulation, model-scale testing will provide the best combination for systematically evaluating the effects of drag-reduction technologies for simulated road conditions. A scale model can be designed to be versatile for installation and model changes.

10.4.1 Tractor-Trailer Scale-Model Testing

The NRC-IAR can also provide additional testing techniques to evaluate the effects of drag-reduction devices on tractor-trailer combinations. Section 11 describes additional technologies that the NRC-IAR can provide for scale-model testing, including aero-acoustic measurement capabilities and snow-ingestion evaluation. Aero-acoustic and snow-ingestion technologies are also available for full-scale testing, and novel technologies for improving road-test measurements and methodologies are considered.

10.4.2 Intercity-Bus Scale-Model Testing

What Are The Factors On The Car That Affect A Cars Drag Coefficient

All aspects of the cars exterior affect the amount of drag a car produces. Its overall shape, the size of its mirrors, how high it sits off the ground, its roofline and even small details like the design of the taillight housing or the radio antenna.

Modern vehicles have been designed to reduce the drag coefficient as much as possible while still making a car thats appealing to the eye. This can be hard to do and if you notice, many vehicles look very similar even if upon further scrutiny they are quite different. Thats the reason most sedans have similar lines and shapes, or why almost all SUVs have the same style roofline. Its about reducing the drag coefficient.

Most people dont give much thought to what the bottom of their car looks like, but its an important part of the vehicle when it comes to drag. If you look at race cars, youll notice that they sit very low to the ground and have flat bottoms. Thats because air does pass over the underside of the car and if your vehicle has something sticking down or simply doesnt have a smooth underbody, its not going to have the drag coefficient it could have.

Also Check: How To Remove Scuff Marks From Car Door Panels