Purchase The Vehicle Project Plan The Build Acquire Tools

Step 1

Purchase a vehicle in fairly good condition if possible. If your project is a pre-1930s vehicle, look for a running example if you can find one. Parts for these cars are difficult to find at the best of times. Ideally, a car project should encompass just three areas: engine restoration, body and paint, and interior restoration. Muscle cars have a considerable aftermarket following in reproduction parts, particularly Mustangs and Camaros. Take popularity and parts availability into account when purchasing the vehicle project.

Step 2

Plan the build by looking at your budget, time frame, and having realistic expectations of what the final product should look like. These factors should be well balanced to produce an enjoyable final product that you will enjoy driving. Make a list of the needed replacement parts, as well as the parts you can repair or clean up yourself. Finally, make a list of steps or parts you will need to farm out to shops. In many cases, engine work, upholstery and paint fall into these categories.

Acquire any tools and literature you will need but don’t already possess to complete the project. Rebuilding a car will require numerous automotive tools, including basic hand tools. Purchasing literature such as engine rebuilding guides, paint guides and automotive reconditioning guides will specifically list specialty tools you will need at each step of the build process.

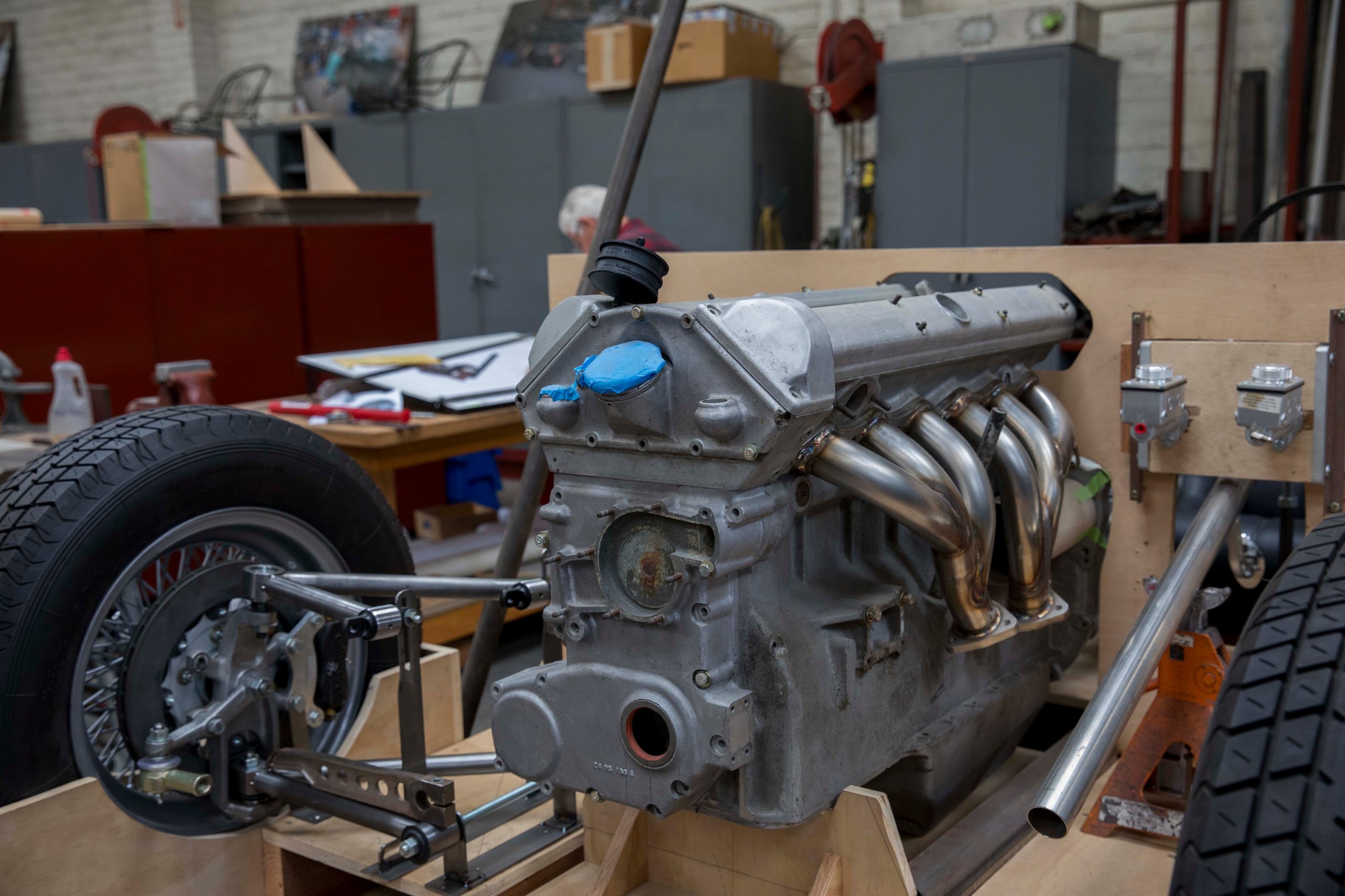

Rebuilding A Classic Car

As this post explains, rebuilding a classic car is in many ways somewhat akin to raising a child. Sometimes you will love it, sometimes you will be pulling your hair out in frustration, but in the end, when its all done, you will be able to stand back and admire what you have created. If that sounds like something worth trying, this plan will tell you everything you need to know about how to get started.

Dont Make This Your Only Vehicle

While its great to build a vehicle that youre going to love and care for, you should have more than just your project car in the garage. If youre focusing on this project so that you have a car to drive to work, its going to be stressful.

Unless you dont need a car on a daily basis, dont make this your primary mode of transportation. Project vehicles should almost always be your second vehicle.

Don’t Miss: How Much Commission Does A Car Salesperson Make

Build Your Own Electric Car

Heres one more plan from Instructables, but this time its a shows you how to build a real car you can drive and in this case, an electric car. Most of the electric cars on the market nowadays are extremely expensive and for many people, out of reach financially. However, if you have a decent dose of DIY acumen and are willing to try something a bit different, you can make your own for a fraction of the cost. And heres the plan that shows you how.

A New Form Of Taylorism

Despite company slogans calling for involvement and empowerment, the authors report, workers at the two plants experienced little that was different from traditional Taylorist mass production on an assembly linewith its narrow, standardized, monotonous tasks repeated every 60 to 90 seconds. Workers at Linden were told they could pull a cord and stop the line to prevent defective products from proceeding, but those who did so were criticized by foremen and eventually stopped trying. Workers at Cami expressed similar frustrations, saying that the plant had turned out to be little different from traditional factories. They decided that management was exploiting them with lower pay and stressful working conditions, and they went on strike a few years after the plant opened. They expressed their dismay by bearing banners with the companys slogans of open communication, empowerment, kaizen, and team spirit crossed out and replaced by the traditional union ideals of dignity, respect, fairness, and solidarity.

Lean production promised participation but increased managerial control.

Also Check: Best Way To Protect Car From Hail

Different Paths To Participation

Is this emphasis on leadership particular to Japan? The managerial ideal in cultures based on Confucian thinking is, to some degree, the benevolent but demanding teacher/leader who creates strong bonds of mutual obligation. But not all Japanese companies are alike. Hondas approach to lean production emphasizes creative conflict, whereas Toyotas approach stresses benevolent hierarchy. And Toyotas leadership ideology is rooted in a rural feudal culture, whereas Hondas team ideology emerged in urban Tokyo. The Toyota worker was typically a farm boy brought by his parents to the factory and handed over to management in loco parentis by contrast, the typical Honda worker was a member of a motorcycle gang who brought a rough egalitarianism to a company that was itself rebelling against the Japanese establishment. Company lore recounts how the engineer who stood up to and disagreed with founder Soichiro Honda eventually became the companys president.

Americans recognize that they need leadership, but they would rather do the leading themselves.

For example, both Toyota and Honda have created effective cross-functional teams that use input from workers to design cars for ease of production. Toyota does so with strong leadership and Honda with team competence. But when U.S. automakers have tried to adopt these approaches, they have foundered as managers of design or engineering have asserted their autonomy and defended their turf.

Harvard Business Review

Use Thin And Light Wheels

Lighter wheels have less friction which means they will go farther than heavier wheels. Remember that the more your wheels weigh, the more they will slow the car down, and the more theyll add to friction. To make the thinnest and lightest wheels you can, its advisable to use CDs and DVDs, or, you can use old vinyl records.

Don’t Miss: How Many Cans Of Freon Does A Ford Expedition Need

How Long Does It Take To Build A Car

As with cost, the timeframe for your build hinges on the kind of project youre looking for, as well as the amount of free time you have to spend on the build. And, just as with cost, your timeline could easily be affected by unforeseen issues and setbacks so its important to be realistic about how long the build will take.

The kit car route will likely be the quickest route to go down for most people. With most, if not all, the parts you need coming in one box, and step-by-step instructions provided, its just a matter of finding the time to put all the pieces together.

Things get a little harder to predict from a timescale point of view when you move away from the kit car route. Whether youre rebuilding an old car or have ambitious plans to build a car from scratch, bodywork fabrication and all, these types of projects will take the longest to complete due to:

- Planning and drawing up blueprints for the project

- Sourcing parts, tools and accessories

- Building complex components or carrying out time-intensive bodywork modifications

- Testing different parts and components to make sure they work safely

- Making sure everything fits together

A week, a month or a year the timescale of your car build is entirely dependent on how much time you can give to the project, as well as the number of setbacks you have along the way.

Measure Twice Spend Once

If youre looking to save money on your vehicle, dont cut corners by buying cheap parts. If you have to sit around and disassemble your whole vehicle, its going to end up costing you more in time and effort than buying quality parts.

Cheap parts break. They have to be replaced with other parts. If you go cheap twice, youll be spending more than if youd bought one higher-quality component. Start with quality over everything else.

Read Also: 888-601-6302

How To Make Car At Home :

After collecting all the materials needed, let us start our science project. Here we have provided step by step guide to make dc motor car.

- First of all let us make wheel part of our school project car. Take coca cola caps and make holes at the middle. soldering rod is used to make holes on the cap. A dremel tool can also be used for this purpose.

- Take a metal rod pass it through coke cap and apply hot melting glue. Pass a straw through metal rod and glue anther cap at opposite end.

Our back wheel is ready. For testing simply hold on stray and try to rotate the wheel. If it rotates freely then our work is perfectly fine.

- Take a dc motor having pulley. Glue this pulley with one coke cap as in video.

- Glue a Popsicle stick at one side of 9 volt battery. And next end of Popsicle stick is glued with dc motor.

- After this glue the back wheel to the middle part pf battery. This gives the shape of our car.

- Now its time to add the wires to battery with dc motor. We also have used switch for better work flow.

Note : as our project is ready . There is necessary of grip at the wheel. For this purpose we have added rubber at the wheels.

- Finally our school science project is ready for demo.

Speed Requires A Spend

Youre only as fast as you can spend. If youre looking to turbocharge your car and add power to your motor, its more costly than slapping turbos onto your car.

Connecting rods wont stay inside of your engine just because you add them. You can abuse your engine if you push on the boundaries of what it can handle.

While you might know what you want, you need to listen to what the engine needs. It should be more than just a turn of a screw to get the horsepower youre looking for.

Secure your engine by investing in it now. An intercooler and better ignition control can pay off later on.

Also Check: Copy Of Florida Car Title

Start With Great Tools

If you want to build your own car from scratch, start with the right set of tools. If you dont have a solid toolbox, youre going to struggle to build your car. You need the right tools for the job to ensure your car is built correctly.

Spending money cant be a challenge for you when it comes to buying tools. If you buy cheap tools, you might as well have the wrong tools. The wrong tools could overtighten or strip bolts.

Theres not point in feeling defeated while building because youve used the wrong tool. Make a comprehensive list of tools and parts so that you can match everything up properly.

Before You Start Know How To Finish

Heres some vital information youll need when building your own car. If you decide to construct a car, youre likely to want to go your own way rather than follow somebody elses plan step-by-step. However, when youre deciding how to go about it, its important that you dont try to be over-ambitious or you risk never finishing the project once you start. So rather than set yourself up to fail, check out this site first and then start a project you will have a better chance of completing.

Read Also: How To Fix A Burn Hole In Car Seat

How To Make A Simple Car Explanation :

We can learn many things with the help of this cool school science experiment. Some of the important topics are noted bellow.

- Science Project Car :

There are lots of science projects. We can make different project and display at school science fair. In all of them a homemade car can be one good idea. A simple dc motor car can be made and demo can be done.

- Dc motor :

A dc motor is simply an electric device that either converts electric energy into mechanical energy or vice versa. When we apply electricity at two terminals of dc motor. Then it passed through magnetic field then a mechanical rotation occurs.

One of the main component of this diy car project is dc motor. There are different types of dc motor. You can get dc motor from electronic store. Or now a days it is easy just order form amazon or any online store.

It is always good to learn about dc motor. How does it works, Flow of current, etc.

In our case wheel starts to rotates . The rotation can be controlled forward or backward via connection of terminals . That is changing the polarity of electric supply.

- Electric Circuit :

Electric circuit is simply a path where electrons flows.

As a student we have to study about electric circuit. Here we have used different electric components such as 9volt battery, switch, dc motor, jumping cable , battery connector, etc.

- Switch :

How To Build A Car

The unmistakable feel of metal scraping skin forces me to look down at my right hand. I see blood welling up from the middle knuckle of my index finger. I had thought that the space beside the transmission tunnel of Local Motors’ Rally Fighter could accommodate both my hand and a seat track. But it couldn’tat least not while I was trying to wrestle the seat into position and bolt it to the floorand now I have a slice in my flesh.

I turn to Mike Pisani, one of Local’s R& D engineers, and explain that he must have ordered a batch of defective seats. There’s no way these fit. He calmly nods toward the other three cars on the line. They all have seats. Which means that if there’s a problem, it’s not with the hardware but with the goon holding the wrench. Therein lies the beauty and the challenge for Local Motors and its customers: You can’t just walk into a dealership and buy a Rally Fighter. You have to roll up your sleeves, grab a ratchet and help build it.

The process that led to my newbie car-building moment can fairly be described as unprecedented. Local Motors CEO John “Jay” Rogers Jr. hatched the idea for Local Motors while he was at Harvard Business School, where the concept won the annual Pitch for Change contest during the 2006 to 2007 academic year. Before Harvard, Rogers had served for six years as a U.S. Marine Corps infantry commander. Which means he could kill you with his bare hands, but he’d have to make a business case for it first.

You May Like: Club Car Models Identification

Tips On How To Start A Car Build

The main issue people looking to build their own car often run into is a lack of resources, be it time, money or space. So, before you take on a DIY car build, ask yourself these three questions:

- Do I have a big enough budget to see the project to completion?

- Do I have the right kind of space for carrying out a car build?

- Do I have time to work on the project and see it through to the end?

In the early stages of planning your project, wed recommend the following as good starting points to tick off:

- Explore similar projects the internet will be your best friend throughout your car build, providing inspiration ahead of the project and help and advice during. Head online and research projects that are similar to your own YouTube is a great starting point, with loads of channels dedicated to showing the realities of building a car from the ground up.

- Research the cost have a look at all the different options and see which best suits your budget this will give a clear ballpark of how much youll likely need to spend. It can help to put different items in a spreadsheet, so you can tot up the prospective cost of things like tools, parts and accessories as you go along.

- Make up a prospective timeline try to work out how long your car build will take by breaking the project up into milestones. For example, constructing the chassis may be the first goal, with the engine build being the next. Be realistic here, setting flexible timescales in line with your own skill level.

Planning A Car Restoration

If you dont want to build a car from scratch but are looking for plans that will help you with a restoration, heres something you should check out. It talks about all the factors you should be taking into consideration when rebuilding a car, it breaks down the cost and sourcing of parts and gives you plenty of useful tips, too. This is part of a series, so you might want to check out their related pages, too.

Also Check: Synchrony Bank Carcareone

What We Love About How To Build A Car By Adrian Newey

There is the potential for How to Build A Car to be highly technical and on the boring side, but what we love about this book is that it is anything but!

It is highly engaging, entertaining, and gives the reader an amazing insight into what goes into winning championship-calibre cars driven by the likes of Nigel Mansell, Alain Prost, Mika Hakkinen, Sebastian Vettel, and others.

Top 10 Tips For A Successful Build

This is another video about building a car in the sense of modifying it and adding to it. This video explains 10 of the most important tips for building your project car the right way so you dont end up overspending or creating a Frankensteins monster of a vehicle that just doesnt feel right. For anyone interested in modding, this video is a must.

Recommended Reading: How To Fill Out A Car Title Florida

Alternative Process For Making Diy Car :

We can make a lot of types of car at home. Some of the well known models of homemade car are mentions above which are cardboard car, rubber band powered car, Dc motor powered car, Electric powered car, match box powered car, Remote control car, etc.

You can make any model mentioned above and demo at your science fair.