What Is An Electric Car Battery And How Does It Work

An electric car battery is an energy accumulator that stores electricity for transmission to an alternating or continuous current engine. However, its importance is far greater than this. The battery is what makes these vehicles sustainable, what releases it from its dependence on fossil fuels. Batteries are at the heart of buyers’ concerns: the car’s range the distance that a vehicle can travel before needing a charge ,its charging time and its price.

The battery world has experienced an unprecedented revolution in the last decade. As a result, the average range of electric cars has increased considerably, terminando así con la denominada range anxiety buyers’ fear of finding themselves stuck on the roadside due to limited range which had been holding back sales. However, range is not the only area of batteries where progress has been made: charging times have also been improved with rapid charging as fast as ten minutes improving their efficiency and their life cycle.

Electric Vehicle Battery Safety

EVs must undergo the same rigorous safety testing and meet the same safety standards required for conventional vehicles sold in the United States as well as EV-specific standards for limiting chemical spillage from batteries, securing batteries during a crash, and isolating the chassis from the high-voltage system to prevent electric shock. In addition, EVs tend to have a lower center of gravity than conventional vehicles, making them less likely to roll over and often improving ride quality.

What Does The Future Hold For Ev Battery Tech

The call for ever-faster charging and ever-further range has led battery makers to explore a range of new technologies for battery development.

Batteries capable of fully charging in five minutes have been produced in a factory for the first time. These new lithium-ion batteries, developed by an Israeli company, StoreDot, are unlikely to come to market before 2025, but the developers believe that by then they will be able to offer 100 miles of charge in a handful of minutes using existing charging infrastructure.

The StoreDot battery replaces its graphite anode with advanced semiconductor nanoparticles which allow for a much faster transfer of ions during charging.

Scientists predict that, because of their much higher density, solid state batteries will be able to hold up to twice the charge of a wet battery. That could, in theory, double the range of EVs to between 400-600 miles on a single charge.

Also Check: Does Autozone Accept Synchrony Car Care

Materials Within A Battery Module

As mentioned earlier, the module houses the individual cells and protects them from vibration and heat. The main container typically uses a mix of aluminium or steel, and also plastic.

The individual battery cells within the module need protection from heat and vibration, so a number of resins are used to provide mechanical reinforcement to the cells within the module:

- Epoxy

- Polyester

How An Electric Car Battery Works

An electric car battery works a lot like the batteries found in laptops and cell phones. In fact, most portable electronic devices use lithium-ion batteries, so you can get a good idea of how your EV battery works by comparing it to your smartphone.

There are two main parts to the battery cycle: Charge occurs when your battery collects and stores electrical energy , and discharge occurs when it converts that stored energy back into electricity.

Just like with your smartphone, an EV battery doesnt always charge and discharge at the same rate. There are fast charging options and slow charging options, and using more power will drain your battery faster. The amount of charge that your battery can hold will also gradually diminish over the course of your batterys life.

You May Like: How To Transfer A Car Title In Az

Materials Within A Battery Cell

In general, a battery cell is made up of an anode, cathode, separator and electrolyte which are packaged into an aluminium case.

The positive anode tends to be made up of graphite which is then coated in copper foil giving the distinctive reddish-brown color.

The negative cathode has sometimes used aluminium in the past, but nowadays is a mix of cobalt, nickel and manganese leading to a mixed-metal oxide material.

The electrolyte is a lithium salt in a dissolved solution known as a solvent . Finally, the is a micro-porous compound which is usually plastic-based such as polypropylene or polyethylene.

What Is In An Ev Battery

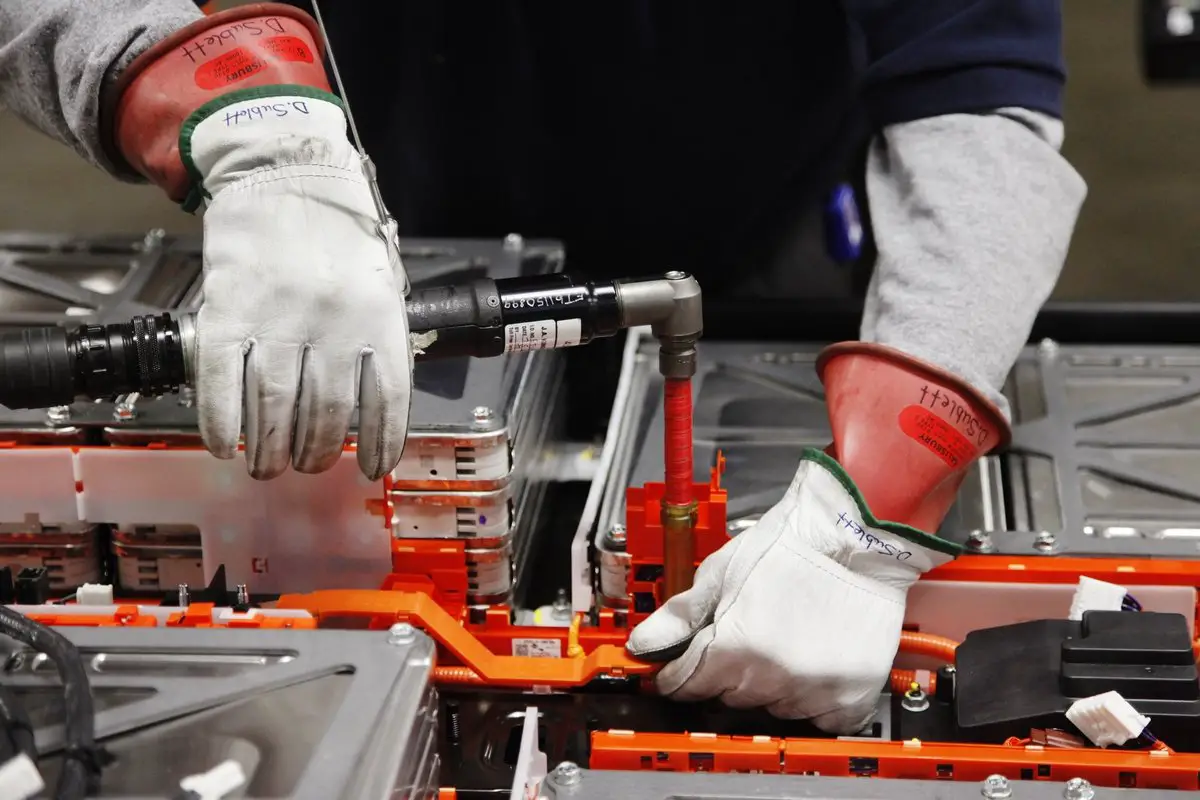

An EV battery is a pack of individual battery cells, each about the size of a AA battery. Those cells are clustered into protective frames called modules, each with its own circuitry, and those modules are clustered together into a pack.

The entire pack is managed by a Battery Management System and a cooling system that regulates the heat and voltage, protects the battery from draining too much or too quickly, and manages the charging and discharging of energy.

EV batteries work by moving lithium ions through a solution called an electrolyte, which carries positively charge ions between separate electrodes called anodes and cathodes. This process creates an electric current that is sent to the EV’s motor.

What the electrodes, separators, and electrolytes are made of can vary. Lithium is the indispensable element, of course, but among the most frequently used other components are aluminum, carbon, cobalt, iron, manganese, nickel, oxygen, phosphorus, and silicon. New combinations and chemistries emerge all the time, using other elements like sodium or tin and sulfur.

You May Like: How To Restore Clear Coat On Car

Cleanrooms & Electric Vehicle Batteries

At the end of the day, when the battery can no longer power the car, the lithium allows it to still be used as energy storage elsewhere. That’s the power of lithium, although the mining practices need work to be considered environmentally friendly.

So what do you think? With mining and manufacturing practices in mind, is lithium batteries still worth it in electric vehicles?What we know is that the production of electric vehicles batteries – along with thousands of other everyday essentials – are produced in cleanrooms to prevent contamination, protect the consumer, and save the manufacturer from incurring the costs of contamination. These are costs like lost productivity, product recalls, damaged reputation, and more.

Do you want to know more about how cleanrooms impact our everyday lives? Check out our Knowledge Center! We’ve broken down all the information you need to know about cleanrooms, particle counters, and more into digestible information. Every day, we rely on cleanrooms but don’t even realize it.

So why not learn more about how this industry impacts your life and business? Learn more in our free Knowledge Center today!

Electric Vehicle Battery Cost

The price of lithium-ion batteries has fallen steeply as their production scale has increased and manufacturers have developed more cost-effective methods.

When the first mass-market EVs were introduced in 2010, their battery packs cost an estimated $1,000 per kilowatt-hour . Today, Tesla’s Model 3 battery pack costs $190 per kWh, and General Motors 2017 Chevrolet Bolt battery pack is estimated to cost about $205 per kWh. That’s a drop of more than 70% in the price per kWh in 6 years!

EVs are forecast to cost the same or less than a comparable gasoline-powered vehicle when the price of battery packs falls to between $125 and $150 per kWh. Analysts have forecast that this price parity can be achieved as soon as 2020, while other studies have forecast the price of a lithium-ion battery pack to drop to as little as $73 / kWh by 2030.

Don’t Miss: Best Paint For Car Interior

Everything You Need To Know About Your Electric Car Battery

Conventional vehicles have an automotive battery thats used to start the internal combustion engine and power the radio, windows, and other electrical components. Youll be familiar with it if youve ever had to because your car wouldnt start.

Electric cars have a different design. They still have an automotive battery usually a 12-volt lead-acid battery, just like the one in a conventional car but they also have a rechargeable battery pack that can be used to power the motor.

If youre thinking of buying an electric car, its important to understand how an electric car battery works and what you can do to maximize your electric car battery life.

Compare EVs Near You

How The Us Plans To Capture The Ev Battery Market

Electric vehicle sales seem to be growing by the minute in the US. Although they still only have a tiny corner of the auto market cornered, astronomical valuations of industry leaders like Tesla offer a glimpse at the potential of a virtually nascent market. In order to bring costs down even further to entice consumers, the US has plans to amplify battery production on its home soil over the next decade. With global competitors miles ahead, does the US have the technology, or more importantly the resources, to gain ground in the EV battery market?

Also Check: Duplicate Car Title Florida Online

How Electric Car Batteries Are Made: From Mining To Driving

The massive 300-550 kg battery packs that go into electric cars are probably the most important component by far, just like the importance of an internal combustion engine to a traditional car. However, the journey that these lithium-ion batteries make when being produced is a very interesting one: from multiple mines in far-off countries to being packaged into a powerful, high capacity battery which can drive a car forward at very high speeds.

So how exactly are these lithium-ion batteries for electric cars made? The short answer is that a number of rare metals need to be dug out of the earth from various mines. These are then packaged into small individual battery cells , before themselves being packed into battery modules. The end result is a battery pack which is made up of multiple battery modules, a cooling system/mechanism and a small electrical power management system. Lets explore some of this in more detail below!

Electric Car Battery Disposal

So what happens when electric car batteries die? Batteries of all forms can prove difficult to dispose of without harming the environment. The same goes for EV batteries. However, EV battery life cycle management works towards solving expensive and toxic disposal of the batteries.

As well as being used to support the use of renewable energy, EV batteries can be refurbished to help power more vehicles in the future. Volkswagen Group has plans to start a recycling project that will see batteries assessed on their quality to determine their future. The batteries with some power left will be given a second life as power packs for mobile vehicle charging. The others that have little to give, will be ground down to a fine powder to extract raw materials such as lithium, nickel, manganese and lithium. The materials can then be rebuilt into more EV batteries.

Also Check: Car Paint Clear Coat Repair

Materials Within A Battery Pack

The battery packs housing container will use a mix of aluminium or steel, and also plastic . The battery pack also includes a battery management system which is a simple but effective electrical item, meaning it will have a circuit board , wires to/from it , and resistors/capacitors which use a mix of materials:

- Metals like copper, nickel, lead, tin and aluminium

- Plastics for the housing like PVC, PET and polystyrene.

Phew, we have really drilled down into the raw materials at play here! One of the things you may have realized is that plastic such as PVC/PET and metals such as steel/copper/aluminium are very common and thus these are not a massive issue for car manufacturers to source: their supply is plentiful both locally and internationally.

However some of the rarer metals that make up a battery cell are not as easy to source, and the rapid rise of electric cars means that greater pressure is placed on rare earth miners than in the past. The next chapter examine how some of these rare metals are mined, so that the battery cells can be manufactured.

How Green Is Your Electric Car Really New Battery ‘passports’ Will Reveal All

Make a more informed, ethical choice

When you’re shopping for a new electric bike, e-scooter, or electric car, a new ‘passport’ for batteries will soon help you understand the effect of its battery on the environment.

As ebiketips reports,the scheme is due to start at the end of 2022, and will tell you all about how and where a specific battery was made, and even how it could be reused once it reaches the end of its life all of which are becoming increasingly important as electric vehicles become mainstream.

The electric vehicle industry is booming, largely thanks to their status as a greener alternative to conventional vehicles, producing far fewer emissions in the form of both gases and particulates. However, EV batteries have their own environmental and social costs.

Also Check: How To Transfer Title In Az

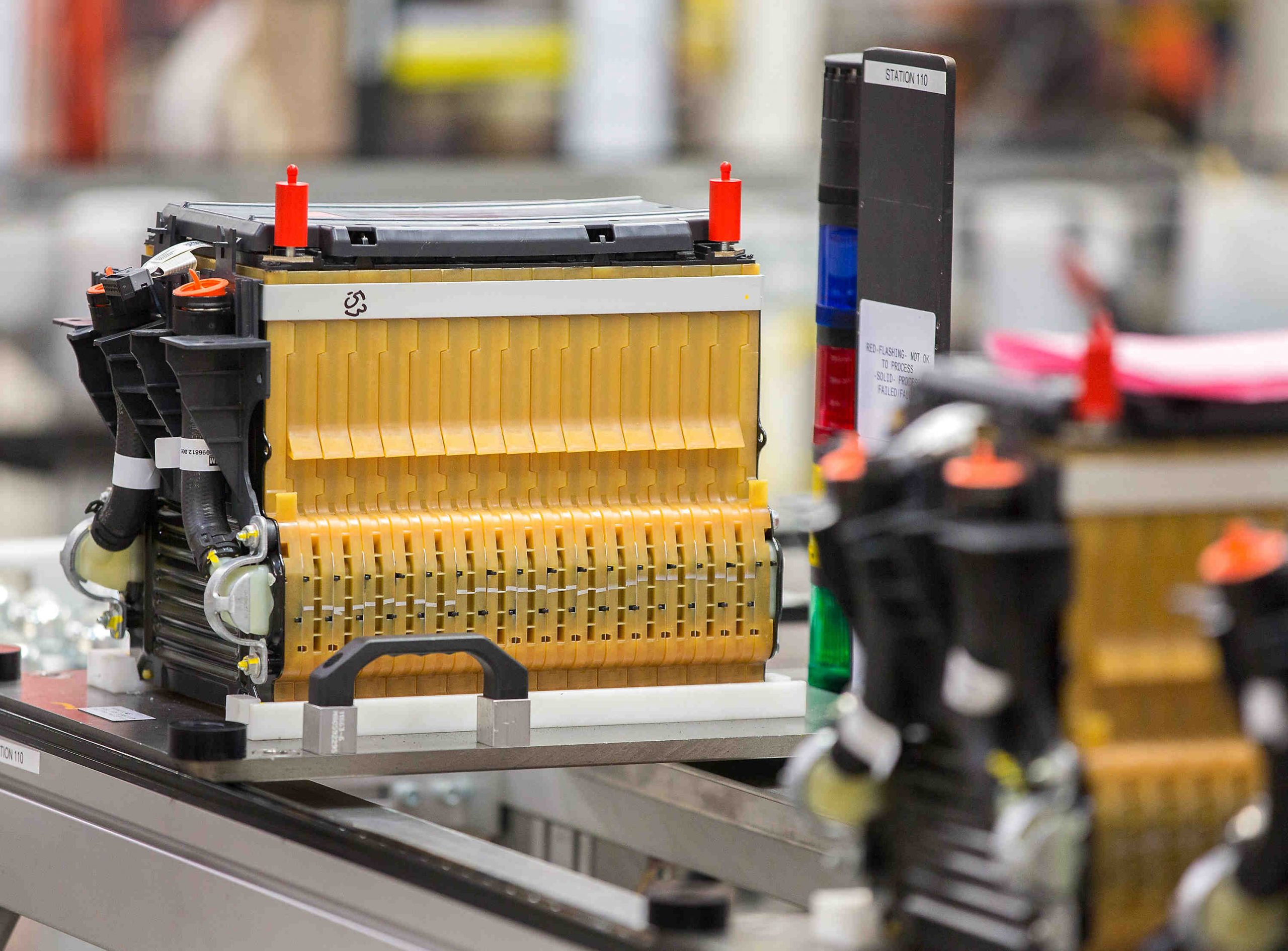

Creating A Battery Module

Just like cell layers were stacked on top of each other to create a battery cell, the finalised battery cells are then stacked on top of each other within a metal or plastic frame which is purpose built.

As mentioned earlier, the module protects the individual cells from both heat and vibrations. This is achieved by applying resins and/or thermal interface material between each cell layer . There might also be more active cooling mechanisms applied, hence the necessary materials will be fitted in-between the cells as well.

Every car manufacturer has a different number of battery cells per battery module: some might have just four cells per module, leading to a module which looks like:

Other car manufacturers may have more cells per module, or they might have much larger battery cells leading to much larger battery modules :

The exact design of the battery is constantly evolving, but the basic idea is that the battery module helps to protect the all-important cells from heat and vibrations/movements.

Electric Vehicle Battery Materials

Most electric vehicle batteries are lithium based and rely on a mix of cobalt, manganese, nickel, and graphite and other primary components. Some of these materials are harder to find than others, though none should be classified as “rare earth metals.”

There are important issues surrounding battery production that must be acknowledged and addressed. For example, over 60% of the global supply for cobalt comes from the Democratic Republic of Congo , which has a poor human rights track record international organizations have denounced for years the exploitative labor practices involved in cobalt production.

Also Check: How To Make Felt Freshies

Electric Cars: What Will Happen To All The Dead Batteries

“The rate at which we’re growing the industry is absolutely scary,” says Paul Anderson from University of Birmingham.

He’s talking about the market for electric cars in Europe.

“It’s something that’s never really been done before at that rate of growth for a completely new product,” says Dr Anderson, who is also the co-director of the Birmingham Centre for Strategic Elements and Critical Materials.

While electric vehicles may not emit any carbon dioxide during their working lives, he’s concerned about what happens when they run out of road – in particular what happens to the batteries.

“In 10 to 15 years when there are large numbers coming to the end of their life, it’s going to be very important that we have a recycling industry,” he points out.

While most EV components are much the same as those of conventional cars, the big difference is the battery. While traditional lead-acid batteries are widely recycled, the same can’t be said for the lithium-ion versions used in electric cars.

EV batteries are larger and heavier than those in regular cars and are made up of several hundred individual lithium-ion cells, all of which need dismantling. They contain hazardous materials, and have an inconvenient tendency to explode if disassembled incorrectly.

Recent proposals from the European Union would see EV suppliers responsible for making sure that their products aren’t simply dumped at the end of their life, and manufacturers are already starting to step up to the mark.

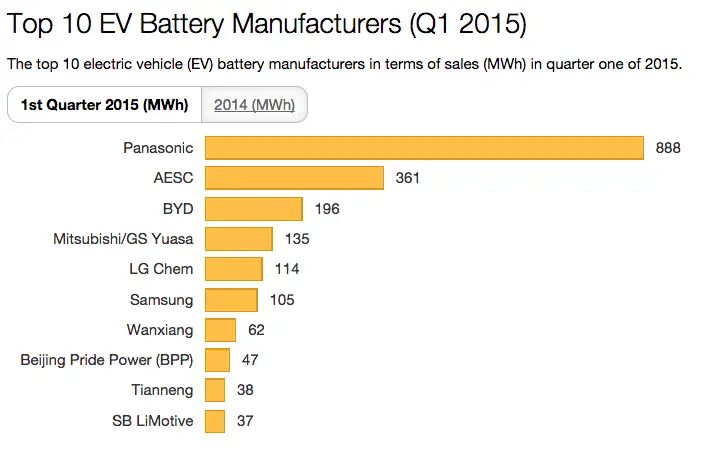

Electric Car Battery Manufacturers

There are a large number of electric car battery manufacturers. Some are well known such as Tesla and Nissan, while others such as BYD or LG Chem, may not be as well-known around the world, but are nevertheless, significant players in the electric car battery manufacturing space. LG Chem, for instance, supply electric vehicle batteries for the likes of Volvo, Renault, Ford and Chevrolet. Not only that, but they have also signed an agreement with Telsa to supply all Telsa produced in China with batteries.

Another major electric vehicle manufacturer BYD is China’s largest electric vehicle manufacturer more than doubled its sales in December 2020 compared to the same time in 2019 and have been selling more battery-powered vehicles since the beginning of 2019. Not only are these battery manufacturers focusing on electric vehicles, but they are also working on battery storage of electricity for residential, commercial and industrial applications.

Also Check: How To Make Car Freshies

Example: Battery Of Tesla Model 3 Electric Car

The Tesla Model 3 is designed to have more than 1,300 charging cycles. This means that the Model 3 can easily travel 300,000 miles before it starts to show any significant signs of battery degradation.

The chemical composition of electric car batteries also keeps changing as we move ahead in time. Currently, Tesla uses a combination of Nickle-Manganese-Cobalt in the ratio of 8:1:1. The most expensive component in this combination is Cobalt.

According to a recent report, Tesla plans to further reduce the proportion of Cobalt in its future electric car batteries. This will help make the upcoming EVs very affordable.

Making The Battery Cell

The first thing to point out is that a battery cell which goes into an electric car is not a round, circular battery like we use in our home electrics . A round battery would not be a very efficient use of space so instead a flat-cell battery cell is produced. This is made up of multiple sheets of cathode, anode and separator which can then be stacked on top of each other like the filling in a Subway! This end result is a cubic shape which is then packaged into an aluminium and plastic frame.

With that said, lets back up a bit and drill down into the detail. The first thing is to create the sheets of cathode and anode, which arrive in the factory as a big metallic calender roll :

This then goes through a set of processes:

You May Like: How Much Do Salesman Make